New generation of luffing jib cranes combining hydraulic jib hoisting technology with the Topless design

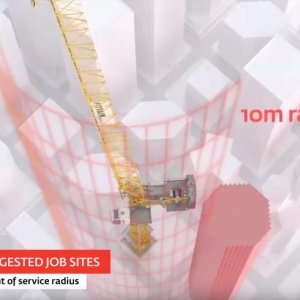

The perfect crane for confined areas

- Almost vertical luffing jib for minimum space requirement when working

- Weathervaning radius optimized for each jib length, just 10 m for the 50 m jib, ideal for congested jobsites

- Option to fit the cab on the left-or right-hand side of the jib according to jobsite needs and especially to allow installation of the crane as close to the building as possible.

The fastest fitting of a luffing jib crane

- One single counter-jib/jib foot package bringing together all of the connected hydraulic functions. No inter-jobsite dismantling/fitting, compact and transportable in one package

- No installation of luffing rope thanks to an innovative hydraulic system: save fitting time compared to traditional luffing system and increased safety

New technologies

- The Topless design with several elements making up the slewing crane part reduce the standard size and weight to make transport, handling, and fitting easier

- The VVH hydraulic system allows complete hoisting of the jib in two minutes

Optimized transport

- Only 4 containers or 4 trucks for transportation of the whole slewing crane part with a 50 m jib

Optimized return on investment

- Luffing jib crane adapted to very tight urban jobsites

- Economical transport, easy and adapted to the fitting sequences

- Fitting/dismantling time reduced through a design combining the Topless concept with hydraulic luffing technology

- Improved fitting safety

- Mast section fleet management optimized through reuse of mast sections type K 1.6 m and 2 m